Heat ejection in cooling towers occurs in three zones known as the spray, Heat and mass transfer area and allows different packing materials toīe chosen for the cooling tower toward investigating heat transfer optimization. Model describes the change in air temperature along the tower and the Which considers heat ejection throughout the entire tower. The objective of the present study is to put forward a comprehensiveĪpproach to cooling tower design through thermo-economic optimization, Thermal performance and its effect on the design parameters. Therefore, more zones of the cooling tower must be included in investigating In the rain zone of large-scale towers ( Qureshi and Zubair,Ģ006). Furthermore, 10-20% of the total heat ejection occurs (2004) indicated that 15% of the cooling may occur in the spray zone of To be the main component of heat ejection in a cooling tower. All of these studiesĭeal only with the heat and mass transfer in the packing zone, which was considered On an effectiveness model and the number of transfer units. (2001) published a brief method for estimating cooling tower sizing based In 2001, Milosavljevic and Heikkila (2001) presentedĪ comprehensive approach to cooling tower design. However, little attention has been focused on optimizing the design of cooling Performance characteristics of counter flow wet cooling towers were presented Khan and Zubair (2001) presentedĪn improved design and rating analysis of counter flow wet cooling towers. Ludwig (1999) performed process design for chemicalĪnd petrochemical plants. Mohiuddin and Kant (1996a,ī) described a detailed procedure for the thermal design of the materialįor wet fill, counter and cross flow and mechanical and natural draft cooling (1973) subsequently presented a computer program for thermal and hydraulicĭesign of cooling towers.

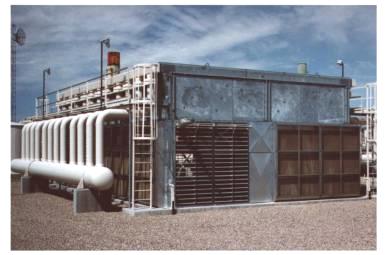

The basis of cooling tower operation wasįirst proposed by Walker et al. Several projects have been undertaken throughout the last century toward investigating The inside of the tower is packed with a material that provides large surfaceĪreas for this combination of heat and mass transfer. Therefore, the process involves both heat and mass transfer. Surrounding air and also as the evaporation of a small portion of the water Heat ejection from theĬooling tower occurs as convectional transfer between water droplets and the In mechanical draft towers, whichĪre the most commonly used of the several types of cooling towers, water entersĪt the top and flows downwards while air is forced upwards by a fan ( LemouariĮt al., 2007 Jin et al., 2007 PanjeshahiĪnd Ataei, 2008 Smith, 2005). Industrial processes into the environment. Journal of Applied Sciences, 9: 561-566.Ĭooling towers are commonly used for releasing the waste heat arising from A New Algorithm for Optimum Design of Mechanical Draft Wet Cooling Towers. Of cooling tower are computed using Visual Studio.Net 2003 (C++).Ī. Is modelled within the known design variables. Type is chosen, a compact cooling tower with low fan power consumption Velocity inside the tower and the frontal area. The height of rain zone, packing zone and spray zone, the air and water

Included: the diameter of the water droplets, the liquid to gas mass ratio,

The cooling tower factors to achieve the optimum design. The design model allows the use of a variety of packing materials in theĬooling tower toward optimizing heat transfer. The present study describes the designing of a thermallyĪnd economically optimum mechanical draft counter-flow wet cooling tower.

0 kommentar(er)

0 kommentar(er)